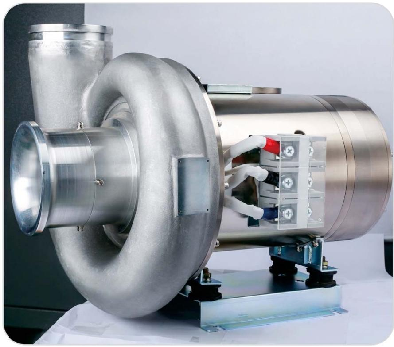

Innovative Air Management Magnetic Suspension High-speed Turbo Blower for Municipal and Emergency Services

- Model

- AS-CZA

Item specifics

- After-sales service

- Support

- Guarantee period

- 3 Years

- Shipment packing

- Custom

- Brand

- AquaSust

- Rated Voltage

- 220V

- Power Source

- Electric Blower

- Color

- Customized Color

Review

Description

Aquasust High Speed Turbo Blower

Suspension high-speed centrifuge is a compressed air production system that appliesa number of technologies such as AirBearing,Impeller, Permanent MagnetSynchronous High Speed Motor, Inverter, Controller, Cooling System, ete. It is asingle-section centrifugal blower that is connected to a Permanent Magnet Synchro-nous Motor driven by an inverter.

Product Characteristics

1.Save Energy

(1)Save 20%~50% energy compared to existing products

(2)Can pay back the initial investment in a short period of time: 2-3 years

(3)Use of high speed operation and high efficiency design

(4)Minimizes mechanical losses through direct connection.

2.Easy To Install And Maintain

(1)Only the inhalation filter needs to be changed periodically

(2)Automatic detection and handling of error content function

(3)No special foundations or anchors are required because there is no vibration.

(4)Minimized installation time

3.Easy Operating

(1)Provides user-friendly interfaces

(2)Provides automatic operation modes as required in the field -Low noise and no vibration below 80dB

(3)Oil-free lubrication system

Core Technology

Original Imported Host

1.The host adopts Korea NAMWON TURBO ONE INC.

2.Stable performance and high efficiency of the mainframe

Suspended Bearing

1.Non-contact, virtually maintenance-free No vibration of bearings, very low noise.

2.Low influence of ambient temperature, dust, etc. Adequate start/stop durability guarantee

IMPELLER

1.Small operating range, high SURGE stability and full pressurization assurance

2.High strength, suitable for high temperature and high pressure severe working conditions.

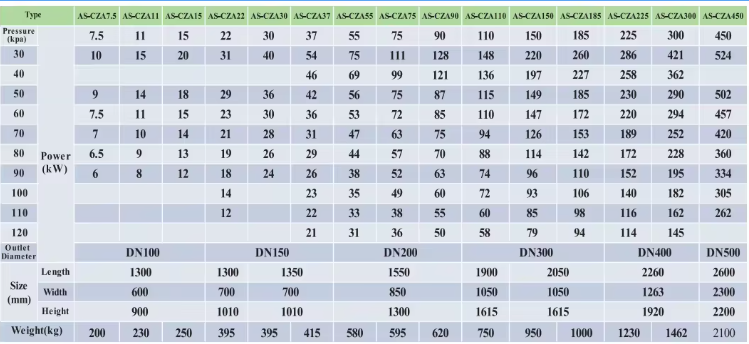

Product Specification

High Speed Centrifuge Turbo Blower Parameter

Application Scenario

Textile mill printing and dyeing wastewater treatment

Paper industry wastewater treatment

Water treatment plant

High Speed Centrifuge Turbo Blower in Municipal and Emergency Services Application

1.Wastewater treatment:

Aeration and Mixing: In municipal wastewater treatment plants, high-speed turbine blowers are used in the aeration system to deliver oxygen to the wastewater to promote microbial growth and degradation of organic matter, as well as for mixing and stirring to maintain an even distribution of suspended solids in the wastewater and to improve the efficiency and quality of wastewater treatment.

2. Sewage pumping station:

Ventilation: In wastewater pumping stations, high-speed turbo blowers can be used in ventilation systems to help remove harmful gases generated in the pumping station, improving the working environment and protecting the health of staff.

3.Emergency services:

Gas transfer: In emergency services, such as fire response and rescue missions, high-speed turbo blowers can be used for gas transfer to provide the required oxygen to the fire scene, to facilitate the combustion process or to provide breathing space.

Ventilation: In emergency situations, such as chemical spills or accident sites, high-speed turbo blowers can be used to provide ventilation, remove toxic gases or hazardous substances, and protect the safety of rescue workers and surrounding residents.

4. Energy saving and environmental protection:

High-speed turbo blowers typically have higher efficiencies than traditional blowers or centrifugal fans, reducing energy consumption and carbon emissions and providing energy-efficient, environmentally friendly solutions for municipalities and emergency services.

FQA

Q: What are disc diffusers made of?

A: Disc diffusers are typically made of materials such as EPDM, silicone, or polyurethane. These materials are chosen for their durability and resistance to chemicals and UV radiation.

Q: How do you choose the right disc diffuser for a specific application?

A:The selection of a disc diffuser depends on factors such as the size of the treatment system, the oxygen demand of the water, and the type of wastewater being treated. A professional engineer or water treatment specialist can help determine the appropriate diffuser for a specific application.

Q:What are some common maintenance tasks for a disc diffuser?

A:Common maintenance tasks for a disc diffuser include cleaning the diffuser discs to remove accumulated debris, checking for leaks in the air supply system, and replacing damaged or worn discs.