Ultra High Speed Turbo Blower:Five Core Technologies Empowering Efficient Energy and Industrial Innovation

- Share

- publisher

- Kate

- Issue Time

- May 20,2025

Summary

Ultra High Speed Turbo Blowershave emerged as critical power equipment due to theirhigh efficiency,energy-saving performance,and compact design.Their technological breakthroughs stem from five core innovations:high-speed permanent magnet motor technology,ultra-high-speed gas foil bearing technology,advanced aerodynamic design,hydrogen fuel cell compressor technology,and modular design.

By: Kate Nana

Post Date: May 20th, 2025

Email:Kate@aquasust.com

Post Tags: Ultra High Speed Turbo Blower:Five Core Technologies Empowering Efficient Energy and Industrial Innovation

Amidst the rapid development of new energy,advanced manufacturing,and hydrogen industries,Ultra High Speed Turbo Blowershave emerged as critical power equipment due to theirhigh efficiency,energy-saving performance,and compact design.Their technological breakthroughs stem from five core innovations:high-speed permanent magnet motor technology,ultra-high-speed gas foil bearing technology,advanced aerodynamic design,hydrogen fuel cell compressor technology,and modular design.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

I.Advanced Aerodynamic Design Technology:The"Heart"of Energy Conversion

Aerodynamic design lies at the core of blower performance,focusing on the optimized integration ofimpellers,diffusers,and volutes.

Key parameters include:

-External performance metrics:Pressure ratio,flow rate,rotational speed,and power output.

-Intrinsic fluid dynamics parameters:Mach number,Reynolds number,specific speed,incidence angle,blade solidity,and velocity triangles.

“Aquasust” employs a proprietary3D-flow impeller model stage,achievinghigher aerodynamic efficiency,broader flow range,and superior application adaptability,widely adopted in fuel cells,environmental protection,textiles,and refrigeration industries.

II.Ultra-High-Speed Gas Foil Bearing Technology:The"Invisible Wings"of Frictionless Support

The gas-floating hydraulic bearing is a special metal foil combination structure that forms an air film based on the Reynolds equation to support high-speed rotors without contact and provide stiffness and damping.

The gas-floating hydraulic bearing is the best choice for bearings of ultra-high-speed machines and equipment, with the characteristics of high speed, no friction, high temperature resistance, small size, pure oil-free, and high efficiency.

Frequent start-stop innovation:

1.Ultra-high-speed rotor lightweighting to minimize inertia.

2.U-Sure’s proprietary bearing patentfor structural wear reduction.

3.U-Sure’s DC coating technologyenhancing material wear resistance.

III.High-Speed Permanent Magnet Motor Technology:The"Power Source"of Precision Drive

The permanent magnet synchronous motor(PMSM)serves as the blower’s power core,delivering:

-High power density(>10 kW/L),efficiency(>95%),and compact size.

-Optimized electromagnetic design:Permanent magnet selection,stator/rotor topology,copper/iron loss reduction,and thermal management ensure operational stability.

Current specifications span10–300 kW rated powerand10,000–180,000 rpm,with enhanced compatibility for coupled rotor systems,cooling solutions,and high-speed drives.

IV.Hydrogen Fuel Cell Compressor Technology:The"Circulatory System"of Green Energy

As a critical component in hydrogen fuel cell systems,the compressor meets stringent requirements:

-High-speed integration:Centrifugal compressors directly driven by PMSM maximize air compression efficiency for cathode-side reactions.

-Oil-free purity:Gas foil bearings and oil-free seals prevent membrane contamination,ensuring fuel cell durability.

-Lightweight modularization:Integrated motor-bearing-compressor units reduce footprint by40%versus conventional designs.

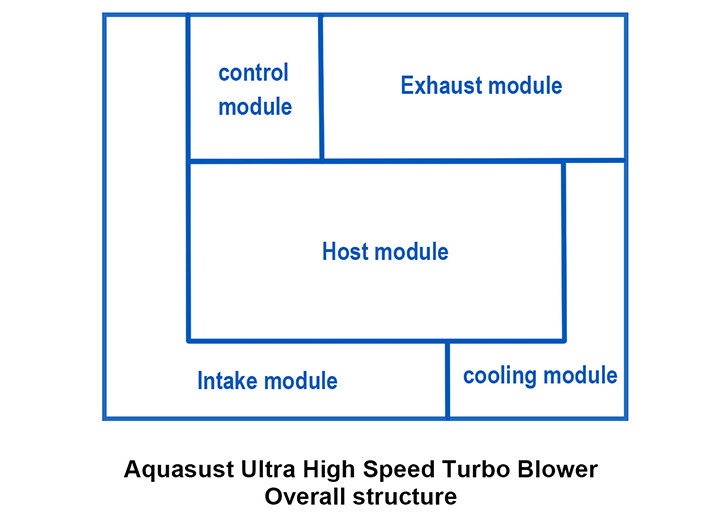

V.Modular Design:The"Genetic Code"of Flexibility

The blower’s modular architecture enables:

Optimize individual modules, targeted design, intelligent management, quickly adapt to needs, improve system reliability and stability, and promote standardization and intelligence

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

By integrating five core technologies,Ultra High Speed Turbo Blowers address traditional limitations–low efficiency,bulkiness,and high maintenance–establishing a"high-efficiency,reliable,green"paradigm for industrial and energy transitions.This technological roadmap not only represents the forefront of advanced equipment but also showcases"Chinese Innovation"and"Chinese Manufacturing"in the global carbon-neutrality race.-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Revolutionize your textile wastewater treatment with our OEM & ODM Ultra-High-Speed Turbo Blower. Low energy consumption, high efficiency!

Optimize your system with our OEM & ODM Rotary Blowers - High-Efficiency, Low-Consumption, Low-Noise design.

Discover high-efficiency Roots blowers for industrial wastewater treatment - OEM & ODM solutions available!

Custom Industrial Blower Systems - Boosting efficiency in Wastewater Treatment for Power Plants.