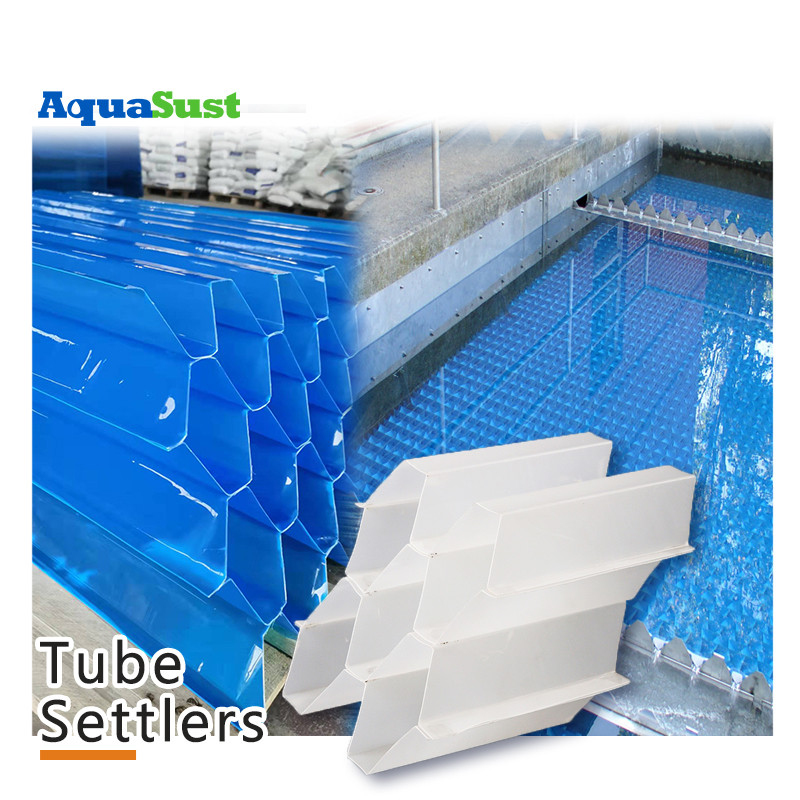

Manufacturer Tube Settler AS-35PP | 35mm Lamella Settler for Shock resistance & Corrosion resistance | for Power Plant Wastewater Treatment

- Price

- US $27-35

- Model

- AS-35PP

- MOQ

- 10 cubic meter

Item specifics

- Material

- 100% New PP with UV protector

- Color

- Blue or white

- Service Life

- 5 to 10 years

Review

Description

Tube Diffuser AS-35PP Introduction

Category: Complementary Products - Tube Settler

Band: AquaSust

Model: AS-35PP

Size: 35mm

Gravity: 0.92g/cm3

Slope: 60°

Tube Settler AS-35PP Advantage

- The AS-35PP tube settler provides a robust solution for water treatment projects with excellent shock and corrosion resistance. This tube settler has been designed with special materials and construction that allow it to withstand sudden load changes and harsh chemical environments, ensuring continuity and stability of the water treatment process. Impact resistance means that the AS-35PP tube settler will remain operational even under extreme water impacts, with no loss of efficiency due to sudden increases in treatment capacity. Corrosion resistance, on the other hand, ensures that structural integrity and functional durability are maintained after prolonged exposure to corrosive chemicals, thus significantly extending the life of the equipment.

Tube Settler AS-35PP in Power Plant Wastewater Treatment Application

1. Improvement of sedimentation efficiency

The inclined tube precipitator significantly improves the sedimentation efficiency of suspended matter by increasing the sedimentation area through the installation of an inclined tube structure in the sedimentation tank. This can precipitate the suspended particles in the wastewater in a shorter period of time, thus improving the solid-liquid separation effect.

2. Reduced footprint

Since the inclined tube precipitator can increase the sedimentation speed and efficiency, it can realize efficient sedimentation in a smaller space. For power plants that require large amounts of wastewater treatment, the inclined tube precipitator can significantly reduce the footprint of the sedimentation tank and optimize the use of space.

3. Improvement of water quality

Through the efficient sedimentation process, the inclined tube precipitator can effectively remove suspended solids and some organic matter in the wastewater, significantly improving the quality of the effluent. The treated wastewater meets the environmental discharge standards and can be safely discharged or further treated for reuse.

4. Reduce the subsequent treatment load

Inclined tube precipitator can remove a large number of suspended solids in the primary treatment stage, reducing the load of subsequent treatment processes, such as filtration, activated carbon adsorption and biological treatment. This not only improves the efficiency of the overall treatment system, but also extends the service life of the subsequent treatment equipment.

5. Handling a wide range of wastewater

There are many types of wastewater in power plants, including cooling water, boiler sewage water, desulfurization wastewater, etc. Inclined tube precipitator is suitable for treating many types of wastewater, has wide applicability, can flexibly respond to different wastewater treatment needs, to ensure the treatment effect.

6. Simple operation and maintenance

Inclined tube precipitator has a simple structure and is easy to operate and maintain. With high degree of automation, it can operate stably and reduce the cost of manual operation and maintenance. Regular cleaning and simple maintenance work can ensure the long-term stable operation of the equipment.

Parameter

Model |

A

|

B

|

C | D | Material | Service Life | Surface Area |

AS-25PP | 30MM | 20MM | <20MM | ⌀25MM | pp+uv | 5-10Year | >95m2/m3 |

AS-35PP | 40MM | 20MM | <20MM | ⌀35MM | pp+uv | 5-10Year | >95m2/m3 |

AS-50PP | 60MM | 28MM | <30MM | ⌀50MM | pp+uv | 5-10Year | >95m2/m3 |

AS-80PP | 80MM | 35MM | <45MM | ⌀80MM | pp+uv | 5-10Year | >95m2/m3 |

Recommended accessories:

Disc Diffuser

Tube Diffuser

Tube Settler

Dewatering Machine