Stainless Steel Wastewater Treatment DAF System Dissolved Air Flotation For Steel Industry Wastewater Treatment

- Model

- Dissolved Air Flotation

Review

Description

Dissolved Air Flotation Introduction

Categories: Dissolved Air Flotation

Brand: AquaSust

Productivity: 1000L/Hour

Weight: 1000kg

Net water: 2(m3/h)

Processing custom: Support

Turbidity of inlet water: 500(mg/l)

Turbidity of effluent: 3(mg/l)

Material: Carbon Steel / Stainless Steel

Application: Solid-liquid Separation

Delievery time: After get the deposit within 15 days

Usage: Wastewater pre-treatment

Dissolved Air Flotation Advantages:

1.Total suspended solids (TSS) reduction up to 97%

2.Chemical oxygen demand (COD) removal up to 85%

3.Low-cost operation and maintenance

4.Standard and customized units meet a variety of application and flow ranges 5.Designed for ease of installation and use

6.Suitable for high-salinity water

Dissolved Air Flotation Introduction Parameters

|

PARAMETERS

|

|||

|

Model

|

Treatment Capacity(m3/h)

|

Dissolved Gas Volum(m3/h) | Weight(T) |

|

ASDAF-5

|

5

|

1-2 | 2.1 |

|

ASDAF-10

|

10

|

2-3 | 3.2 |

ASDAF-20 | 20 | 5-7 | 3.6 |

ASDAF-30 | 30 | 6-10 | 3.9 |

ASDAF-50 | 50 | 15-20 | 5.6 |

ASDAF-80 | 80 | 24-32 | 7.6 |

ASDAF-100 | 100 | 30-35 | 11.5 |

ASDAF-150 | 150 | 60-80 | 15 |

ASDAF-200 | 200 | 80-100 | 19 |

ASDAF-250 | 250 | 110-120 | 23 |

ASDAF-300 | 300 | 120-180 | 26 |

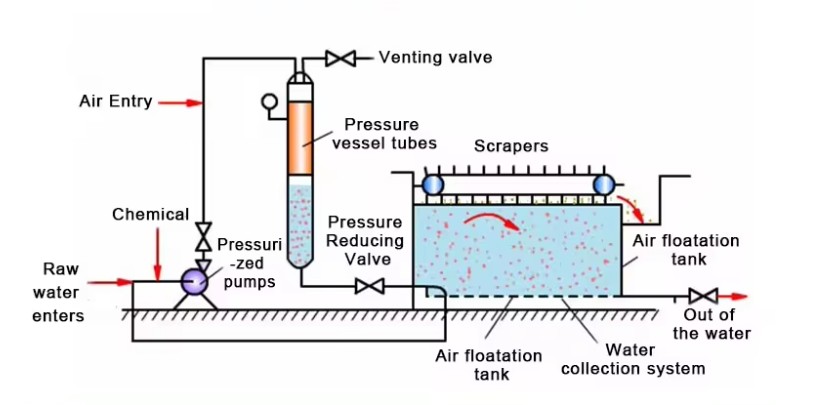

DAF Working Principle

Application in Steel Industry Wastewater Treatment Application

1. Removal of suspended solids

Iron and steel industrial wastewater usually contains a large number of suspended solids, these suspended solids are mainly from the steel production process of iron filings, oxidized skin, etc. DAF through the release of dissolved air in the water to form tiny bubbles, these bubbles attached to the suspended solids, so that it floats to the surface of the water, thus realizing the high efficiency of the removal of suspended solids.

2. Removal of grease and floating oil

A large amount of lubricating oil and coolant is used in the steel production process, which can contaminate the wastewater. DAF is able to effectively remove grease and oil slicks from wastewater, as the air bubbles attach to the oil droplets, causing them to collect and float to the surface of the water, forming a scum layer that is easy to collect and remove.

3. Removal of heavy metals

Iron and steel industry wastewater often contains heavy metal ions, such as iron, zinc, chromium and so on. Through DAF, these heavy metals can be removed together with the precipitates generated by the reaction of flocculants. The air bubbles bring these sediments to the water surface in the process of uplifting, forming flotsam, which achieves the purpose of removing heavy metals.

4. Improve sludge dewatering performance

The concentration of suspended solids in wastewater after DAF treatment is significantly reduced, which makes the subsequent sludge treatment process more efficient.DAF removes a large amount of suspended solids and floating oil, which can significantly reduce the load on the sludge dewatering equipment, improve the performance of sludge dewatering, and reduce the amount of sludge generated.

5. Stabilization of wastewater treatment process

DAF, as a pretreatment process, can significantly reduce the concentration of suspended solids, oil and grease and some organic matter in wastewater, provide more stable influent conditions for subsequent biochemical treatment (such as activated sludge, MBBR, etc.), and improve the stability and efficiency of the overall treatment system.

6. Reduced operating costs

DAF pretreatment reduces the load of the subsequent treatment process, reduces the use of chemicals and treatment time, thus reducing the overall operating costs of wastewater treatment. At the same time, the DAF system also reduces labor costs due to its easy operation and high degree of automation.

7. Improvement of treatment effect

DAF treatment can significantly improve the clarification and transparency of wastewater, and the effluent water quality can meet or exceed the discharge standards. This is beneficial to environmental protection for iron and steel companies and also meets the requirements of increasingly stringent environmental regulations.