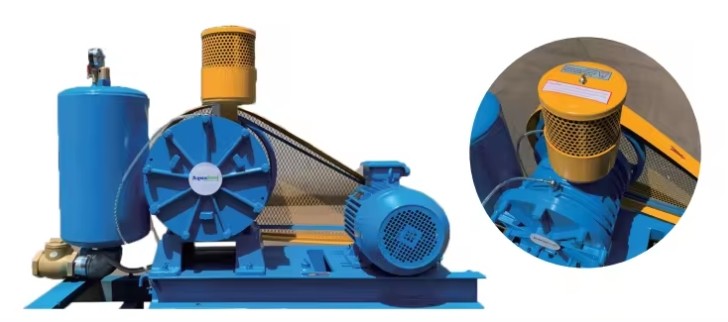

High-Efficiency, Low-Consumption, Low-Noise Rotary Blowers for Garbage Leachate Treatment

- Model

- AS-SL7018

Review

Description

HC-S Series Structure And Working Principle

Blower pressure range: 0.1-0.5 kgf/cm2

The rotary blower has a compact structure and is mainly composed of the following six parts: motor, air filter, blower main unit,air chamber, and base (cum oil tank). and oil drip nozzle.

The blower operates eccentrically with an offset rotor in the cylinder, and the volume change between the blades in the rotor groove draws in. compresses, and exhales air. During operation, the pressure difference of the blower is utilized to automatically send lubricant to the drip nozzle. which drains into the cylinder to reduce friction and noise, and at the same time reduces the return flow of gas inside the cylinder.

Product Features

1. Low noise, large air volume, energy saving, smooth operation, easy installation

2. Resistant to load changes, stable airflow, air chamber attached, smooth air dispersion.

3. Excellent material, ingenious structure, excellent performance.

Rotary Blower Electronic in Garbage Leachate Treatment Applications:

1. Aerobic biological treatment

In the aerobic biological treatment unit of the leachate treatment, the rotary fan electronic control system ensures that there is sufficient dissolved oxygen in the system by providing precise airflow control to promote the growth of aerobic microorganisms and the degradation of organic matter.

2. Ammonia and Nitrogen Removal

Leachate usually contains a high concentration of ammonia and nitrogen. The rotary fan electronic control system can effectively remove ammonia and nitrogen and improve effluent water quality by providing appropriate airflow to promote nitrification and denitrification processes.

3. Membrane Bioreactor (MBR)

In MBR system, the airflow provided by the rotary fan electronic control system not only helps oxygen transfer, but also reduces membrane contamination, prolongs the service life of the membrane, and improves the treatment efficiency of the MBR system.

4. Air flotation device

In an air flotation unit, the rotary fan electronic control system helps to remove suspended solids and oils from the leachate by providing a steady airflow, improving treatment efficiency and effluent quality.

5. Sludge Treatment

In sludge treatment, the rotary fan electronic control system promotes aerobic stabilization and dewatering of the sludge by regulating the airflow, improving treatment results and reducing sludge volume and treatment costs.

Recommended accessories:

Disc Diffuser

Tube Diffuser

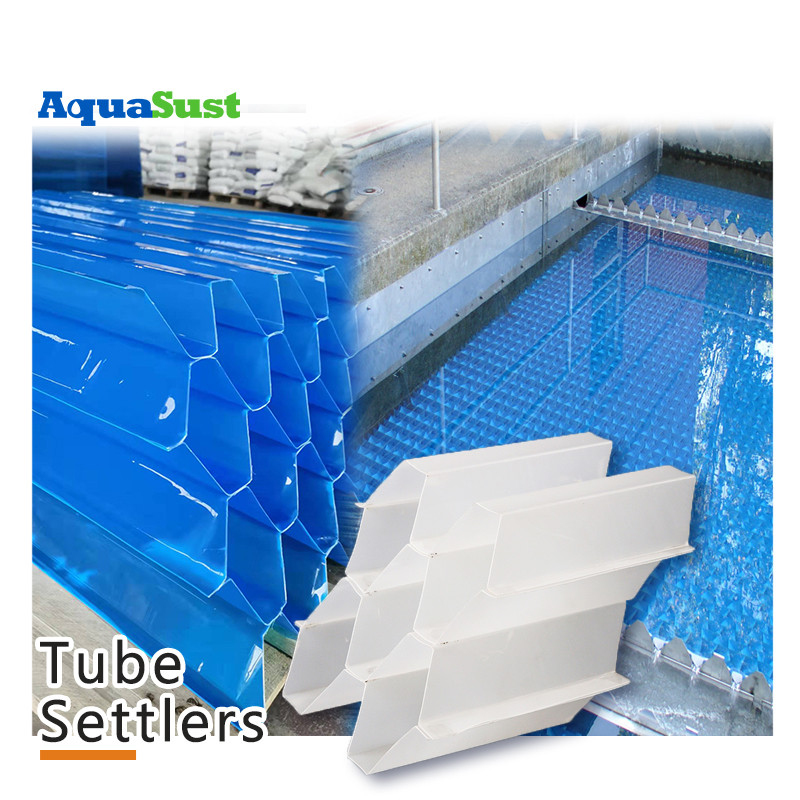

Tube Settler

Dewatering Machine