Manufacturer Disc Diffuser AS-DD270 |9"Fine Bubble Diffuser Uniform Bubble Distribution And High Aeration Efficiency | For Textile And Dyeing Wastewater Secondary Treatment

- Price

- US $8-10

- Model

- AS-DD270

- MOQ

- 100 piece

Item specifics

- Membrane Material

- EDPM, Rubber,Silica Gel

- Connector

- 3/4"NPT male thread

- Plate Color

- Black, White, Gray, Black

Review

Description

Disc Diffuser AS-DD270 Introduction

Category: Biochemical Tank - Aeration Diffuser

Brand: AquaSust

Model: AS-DD270

Size: 9 inch 270MM

Membrane Material:EPDM 8600N from EXXONMOBIL USA

Carrier Plate:Formula Strengthen ABS Material

Connector:3/4" NPT Male thread

Bubble size(mm):1.0-2.0

Design Flow(m3/h):3.0-4.0

Flow Range(m3/h):1.5-8.0

Standard Oxygen Transfer Efficiency(6m submerged):≥38%

Service Area(m2):0.25-1.0

Service Life(years):3 to 7

Number of perforations(Pcs):6600

Use of Temperature(℃):0-80

Disc Diffuser AS-DD270 Advantage

1. Multiple integral check valves keep your aeration pipingsystem clean.( Membrane check Valve A and Structure checkvalve B together)

2.High quality Juntai EPDM Membrane can guranateelonger service life.

3.Durable O-ring rubber seal, high quality accessories, durable.

4.Formula ABS Disc Support which made by ABS withstrength formula and UV protector. when install or rechange water,there are some sunlight throught water make the ABS plasticshorter life, AquaSust Formula ABS can be volid such problem.AquaSust Disc supportcan be used for more than 15 years. Ifneed.ifthe membrane is not good enough, we can just change themembrane is OK

5.Eight Ribs make the ABS Support Sthrength enough for longservice life of 5 to 10 years

Disc Diffuser AS-DD270 Application

The AS-DD270 Disc Diffuser has a crucial role in the secondary treatment of textile and dyeing wastewater. Wastewater from the textile and dyeing industries usually contains high concentrations of organics, pigments, and chemical additives that are highly toxic to the environment and difficult to biodegrade. Disc aerators effectively remove pollutants from wastewater by providing fine and uniformly distributed bubbles that effectively increase the amount of dissolved oxygen in the water column, promoting microbial growth and biodegradation of organic matter.

The high oxygen transfer efficiency of this type of aerator is particularly suitable for treating complex organic matter in textile and dyeing wastewater, which requires large amounts of oxygen to sustain microbial metabolic activity. The ability of disk aerators to provide higher oxygen utilization at lower energy consumption is because they produce smaller bubbles, which increases the contact area of the bubbles with the water, thereby increasing the oxygen dissolution rate and transfer efficiency. In addition, the uniform bubble distribution of the disk aerator helps to ensure the consistency of microbial activity at all points in the treatment process, ensuring stable and efficient wastewater treatment results.

The use of disk aerators in textile and dyeing wastewater treatment not only significantly improves wastewater treatment efficiency and quality, but also reduces operating costs due to their low energy consumption and high durability. Their robust design and durable material choices, such as EPDM, ensure long-term stability and low maintenance requirements, maintaining efficient operation even when treating wastewater containing complex chemicals. As a result, disk aerators have become an indispensable tool in the secondary treatment of textile and dyeing wastewater, helping factories meet environmental standards while achieving cost-effective operations.

Parameter

|

No.

|

Item No.

|

AS-DD270

|

|

1

|

Bubble Type

|

Fine Bubble

|

2 | Plate Diameter | 270mm |

3 | Membrane Diameter | 9 inch |

4 | Membrane Material | EDPM, Rubber,Silica Gel |

5 | Base Material | ABS, ABS + Glass Fibre,PP PP+ Glass Fibre |

6 | Connector | 3/4"NPT male thread |

7 | Weight | 0.62KG |

8 | Plate Color | Black, White, Gray, Black |

9 | Membrane Thickness | 2mm |

10 | Bubble Size | 1-2mm |

11 | Design Flow | 3-4 m3/h |

12 | Flow Range | 1-8 m3/h |

13 | SOTE | ≥38% |

14 | SOTR | ≥0.45kg O2/h |

15 | SAE | ≥8.9kg O2/kw*h |

16 | Headloss | 1500-4300Pa |

17 | Service Area | 0.25-1.0 m2/pcs |

18 | Service Life | > 7years |

Recommended accessories:

Disc Diffuser

Tube Diffuser

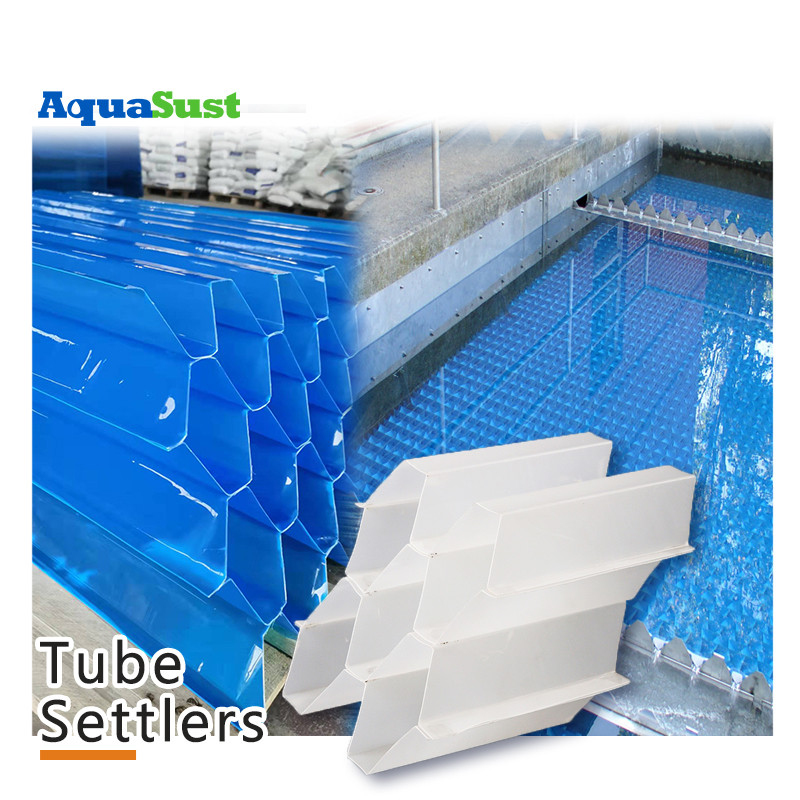

Tube Settler

Dewatering Machine