What Is The Working Principle Of MBBR? What Pollutants Does It Remove From Wastewater?

- Share

- publisher

- Kate

- Issue Time

- Apr 8,2024

Summary

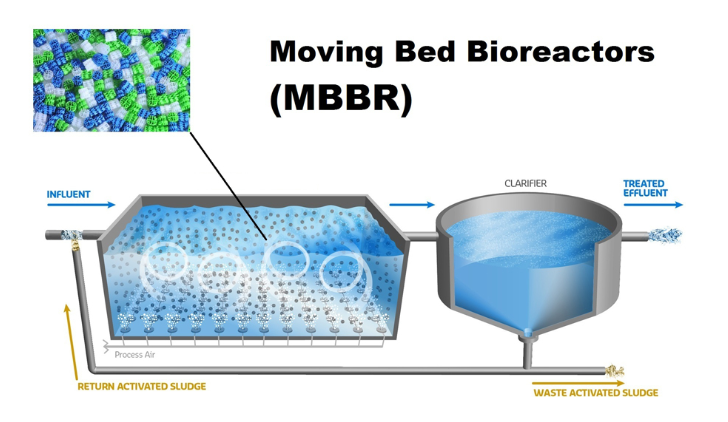

This paper describes MBBR as a wastewater treatment technology that combines the advantages of activated sludge and biofilm systems. Through the use of polyethylene biofilm carriers filled with free-moving polyethylene in an aerobic wastewater treatment tank, MBBR utilizes the microorganisms (biofilms) growing on these carriers to treat wastewater.

What Is The Working Principle Of MBBR? What Pollutants Does It Remove From Wastewater?

By: Kate Nana

Post Date: April 8th, 2024

Post Tags: MBBR, Secondary Wastewater Treatment, MBBR System,Moving Bed Biofilm Reactor (MBBR)

Table Of Contents

1. The Principle of Moving Bed Biofilm Reactor (MBBR)

2. The Benefits of Simultaneous Nitrification and Denitrification Reactions

3. What does MBBR remove?

4. How does Moving Bed Biofilm Reactor (MBBR) work?

The Principle of MBBR

The MBBR (Moving Bed Biofilm Reactor) process combines the advantages of traditional fluidized beds and biocontact oxidation methods, making it a new and efficient method for wastewater treatment. This process relies on aeration and the uplifting action of water flow in the aeration tank to keep the carriers in a fluidized state, thereby forming suspended activated sludge and attached biofilms. Thus, the moving bed biofilm utilizes the entire reactor space, fully leveraging the advantages of both the attached and suspended biomass phases, complementing each other’s strengths. Unlike previous fillers, the suspended filler can come into frequent and multiple contact with wastewater, hence being termed a "moving biofilm."

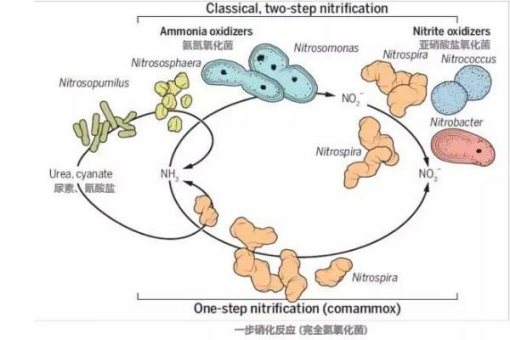

The principle of the MBBR process is to add a certain amount of suspended carriers to the reactor, increasing the biomass and variety of organisms in the reactor, and thereby enhancing the reactor's treatment efficiency. Since the density of the filling material (0.96-0.98kg/l) is close to that of water, it is completely mixed with water during aeration, creating an environment for microbial growth in gas, liquid, and solid phases. The collision and shearing of carriers in the water make the air bubbles finer, increasing the utilization rate of oxygen. Additionally, each carrier harbors different types of organisms inside and outside, with anaerobic or facultative bacteria growing inside and aerobes on the outside, making each carrier a micro-reactor. This allows nitrification and denitrification reactions to occur simultaneously, thus improving the treatment effect.

The Benefits of Simultaneous Nitrification and Denitrification Reactions

1. Nitrogen Removal: The combination of nitrification and denitrification enables the system to effectively convert ammonium nitrogen (NH₃-N) in the water into gaseous nitrogen (N₂), achieving nitrogen removal. This plays a crucial role in preventing and controlling water eutrophication and high concentrations of ammonium nitrogen in the water.

2. Environmental Balance: Through the balance of these two processes, nitrogen in the water can be effectively treated under different environmental conditions (such as aerobic and anoxic), ensuring the flexibility and stability of the water treatment system.

3. Energy Saving and Emission Reduction: Compared with physical and chemical methods, the biological nitrification and denitrification processes can achieve nitrogen removal with lower energy consumption and reduce the use of chemical agents, benefiting environmental protection and sustainable development.

The simultaneous existence of nitrification and denitrification also means that the design and operation of the water treatment system require precise control, including adjusting the conditions of aerobic and anoxic environments, to ensure the effective progress of these two processes. Furthermore, this means that the MBBR system can handle a wider range of pollution loads, improving the adaptability and efficiency of the water treatment system.

What Does MBBR Remove?

1. Organic Matter: Moving Bed Biofilm Reactor (MBBR) effectively removes organic pollutants dissolved in water, such as BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand), which typically come from domestic sewage, industrial wastewater, and agricultural runoff. MBBR can achieve a BOD removal rate of over 90%.

2. Ammonia Nitrogen: Through the biological oxidation process, namely nitrification, MBBR can convert ammonia nitrogen into nitrate, thereby reducing the ammonia nitrogen content in the water. This process is crucial for preventing eutrophication of water bodies and enhancing water quality safety. The removal rate of ammonia nitrogen can reach over 90%. The actual removal rate is affected by the activity of nitrifying bacteria in the system.

3. Total Nitrogen (TN): The MBBR process effectively removes total nitrogen through nitrification and denitrification, converting ammonia nitrogen and organic nitrogen into gaseous nitrogen (N₂), thus reducing the nitrogen content in the water body. The removal rate of total nitrogen can reach 50% to 80%. With optimized system design and operating conditions, sometimes even higher removal rates can be achieved.

4. Total Phosphorus (TP): Although MBBR is primarily a biological nitrogen removal process, it can also remove phosphorus from water to a certain extent by optimizing operating conditions and combining with other treatment units (such as chemical precipitation), reducing the risk of eutrophication. However, by combining with physicochemical processes such as chemical precipitation, a total phosphorus removal rate of 50% to 90% can be achieved.

5. Suspended Solids (SS) and Particulate Matter: In the MBBR process, some microbes attach to carriers to form a biofilm, while others exist in a suspended form. This helps remove suspended solids and particulate matter from the water. The MBBR process can effectively reduce the content of suspended solids in water, with a removal rate typically between 50% and 90%.

6. Pathogens: The biofilm in the MBBR process has a certain adsorption and degradation effect on some pathogens, thereby reducing the pathogen content in the water to a certain extent and improving water quality.

The advantages of the MBBR process include its efficiency, small footprint, and ease of expansion and upgrading. This makes the MBBR technology one of the widely used technologies in modern urban sewage treatment and industrial wastewater treatment.

How Does MBBR Work?

Under aerobic conditions, the buoyancy of air bubbles generated during aeration can drive the movement of the media and the surrounding water body. As the airflow passes through the water stream and the gaps in the media, it is obstructed by the media and split into small bubbles. In such a process, the media is thoroughly stirred and mixed with the water flow, and the airflow is sufficiently divided into fine bubbles, increasing the contact and oxygen transfer efficiency between the biofilm and oxygen.

Under anaerobic conditions, the water flow and media are fully fluidized under the action of a submerged mixer, achieving the purpose of full contact and degradation between the biofilm and the treated pollutants.

The core of the MBBR process is to achieve full fluidization of the suspended carrier media to enhance the treatment of pollutants. In the practical application of the MBBR process, factors to consider mainly include the bioreactor pool type, the additional amount of suspended media, the aeration system, the interception screen, propellers, etc.

Fluidization of the biological media in the aeration zone is key to the system's good treatment function. This is mainly achieved by the aeration system in the aerobic zone of the bioreactor. An appropriate aeration system in the aerobic zone can ensure the fluidization effect of the biological carrier media, ensuring that the fluidized media moves up and down, back and forth in the water body, allowing the media to fully mix, collide, and contact with the wastewater, effectively completing the contact, exchange, and adsorption processes among pollutants, water, and air. The specific gravity of the media is generally chosen between 0.94-0.97. During the bacteria culturing period, the media surface will gradually adhere to a large amount of biofilm. The greater the attachment, the gradually increasing specific gravity, when the biofilm on the media reaches a certain thickness, its specific gravity exceeds 1, causing the media to sink to the bottom of the pool from the non-aerated area. The impact force at the bottom of the aeration area is the strongest, which can quickly wash away the residual biofilm on the media. After the biofilm is shed, the specific gravity of the media also decreases to below 1 and rises in the aeration area. Based on the change in specific gravity before and after film attachment, the media can tumble in the aeration and non-aeration zones, thus alternating the growth and shedding of the biofilm, ensuring the stability and activity of the biofilm quantity, making the process operate more steadily. To prevent the fluidized suspended media from entering the next stage with the mixed liquor, a screen is appropriately designed and used for simple interception and separation in the aerobic zone. The screen material is made of stainless steel, and the type is matched with the suspended media.