How To Calculate Aeration Volume For AquaSust Diffuser

- Share

- publisher

- Kate

- Issue Time

- Jul 2,2024

Summary

AquaSust Diffuser, as one of the common aeration devices, play a significant role in this process. Properly accounting for the aeration volume of an aeration disk is essential for optimizing the efficiency and effectiveness of the aeration system. This article delves into the methods and considerations for accurately measuring and accounting for the aeration volume of AquaSust Diffuser.

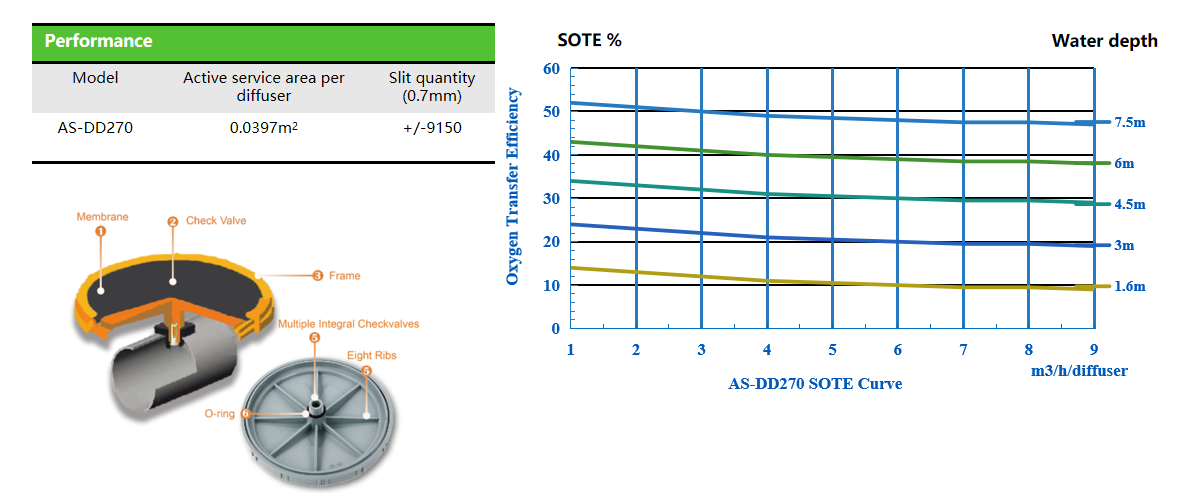

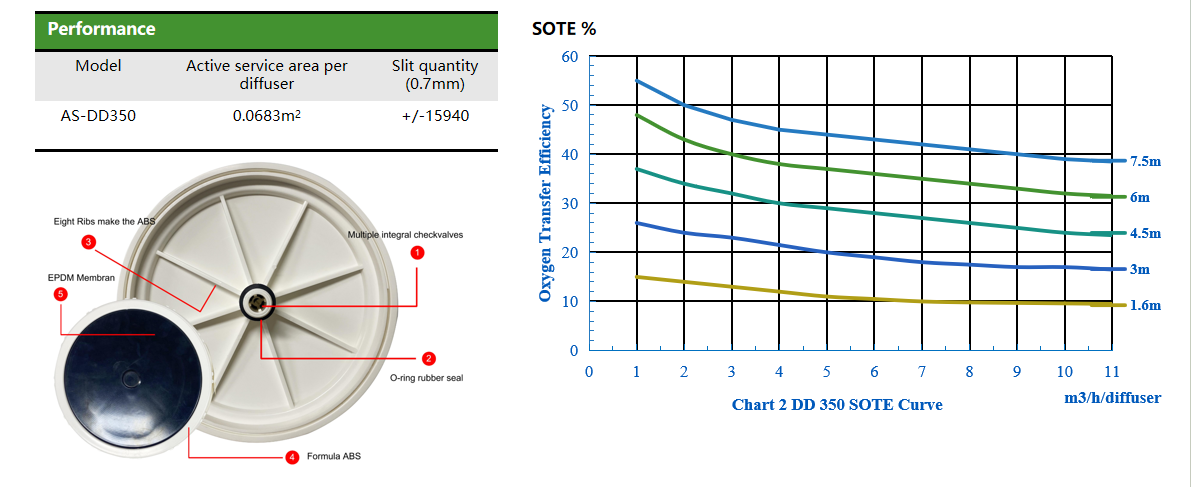

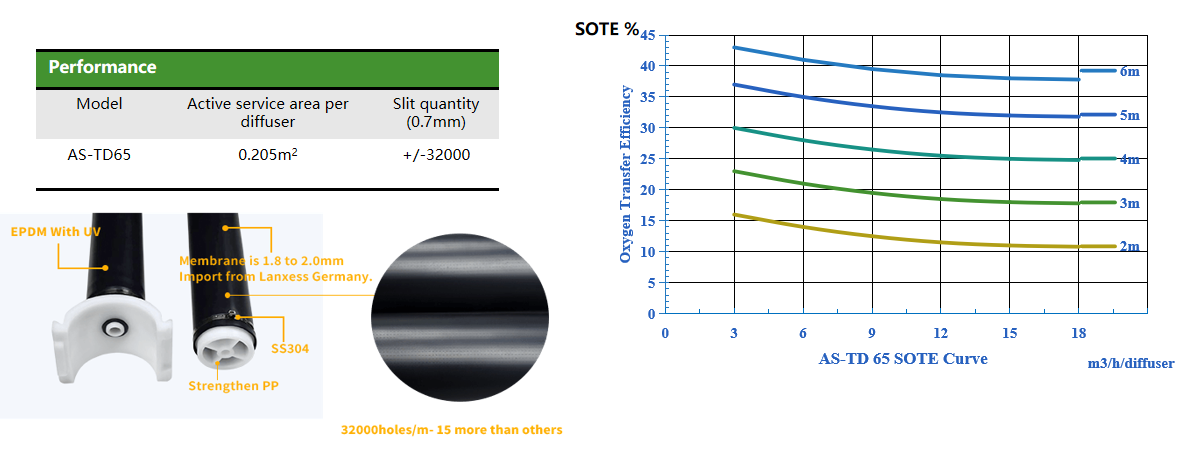

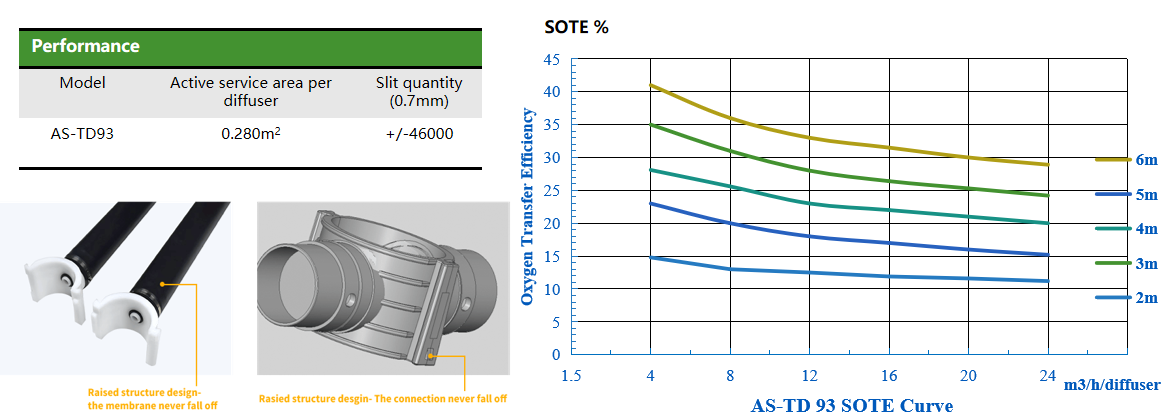

4. Calculate The Oxygen Supply Capacity Of A Single AquaSust Diffuser

Oxygen supply capacity of a single diffuser = OTE × gas volume (usually in Nm³/h)

AS-DD215 Standard aeration volume: 2 Nm³/h

AS-DD270 Standard aeration volume: 3 Nm³/h

AS-DD350 Standard aeration capacity: 5 Nm³/h

AS-TD63 Standard Aeration: 7 Nm³/h

AS-TD93 Standard Aeration: 12 Nm³/h

AS-TD113 Standard Aeration: 20 Nm³/h

5. Determine the number of aeration trays required:

Total oxygen demand ÷ Oxygen supply capacity of a single aeration pan = number of disc diffuser required