Precision and Efficiency Combined Welding Gun For Industrial Repair And Maintenance

- Price

- US $30

- Model

- welding gun

- MOQ

- 1 piece

Item specifics

- Head style

- Chisel

- Handle material

- Wood

- Special feature

- Portable

- Power

- 100W/200W/300W

- Power source

- Corded Electric

Review

Description

Welding Gun Introduce

The welding gun is the hand-held tool used for welding, usually in conjunction with a welding power source and wire supply system. It joins workpieces together by heating the wire to a molten state through an electric arc. The design of a welding gun usually includes a handle, trigger, electrode and nozzle to control the arc and wire flow.

Welding Gun Advantages

2. Precise control: The torch provides precise control of current and voltage, resulting in an even and beautiful weld seam with fewer welding defects.

3. Versatility: Suitable for a variety of welding processes and materials, including steel, stainless steel, aluminum and its alloys.

4. Portability: The welding torch is usually designed as a hand-held, lightweight, easy to operate, suitable for a variety of working environments.

5. Safety: The welding torch is equipped with a protective gas system, which effectively prevents harmful gases generated during the welding process and improves operational safety.

Welding Gun In Construction Project Application

1. Equipment Repair

Fabrication and Replacement: Welding guns are used to fabricate and replace parts of industrial machinery and equipment, such as broken or worn-out components.

Structural Repairs: They help in repairing structural components of machinery, such as frames, housings, and supports, which might have been damaged due to wear and tear or accidents.

2. Pipe and Tube Repair

Pipeline Maintenance: Welding guns are employed to repair leaks or cracks in pipelines used for transporting liquids, gases, or slurries. This is crucial in maintaining the integrity of the pipeline systems.

Tube Fabrication: They are used to repair and fabricate tubes and pipes in industrial systems, ensuring that the systems remain functional and efficient.

3. Structural Component Maintenance

Support Structures: Welding guns are used to repair or reinforce structural supports and frameworks in industrial settings, such as supports for conveyors, silos, or heavy machinery.

Steel and Metal Structures: They help in maintaining and repairing steel structures, including beams, columns, and plates, which are integral to various industrial facilities.

4. Machine Maintenance

Component Welding: Welding guns are used to weld components of machines that are subject to high stress or wear, such as gears, shafts, and housings.

Tool Repair: They assist in the repair of industrial tools and equipment that may suffer from damage or degradation during use.

5. Custom Fabrication

Custom Parts: Welding guns are used for custom fabrication of parts that are not readily available or are required to meet specific design criteria.

Modifications: They are employed to modify existing equipment or structures to better fit the needs of the industrial process or to integrate new components.

6. Maintenance of Heavy Equipment

Mining Equipment: Welding guns are used to repair heavy mining equipment, such as excavators and dump trucks, ensuring their operational efficiency.

Construction Machinery: They help in maintaining and repairing construction machinery, including bulldozers, cranes, and loaders.

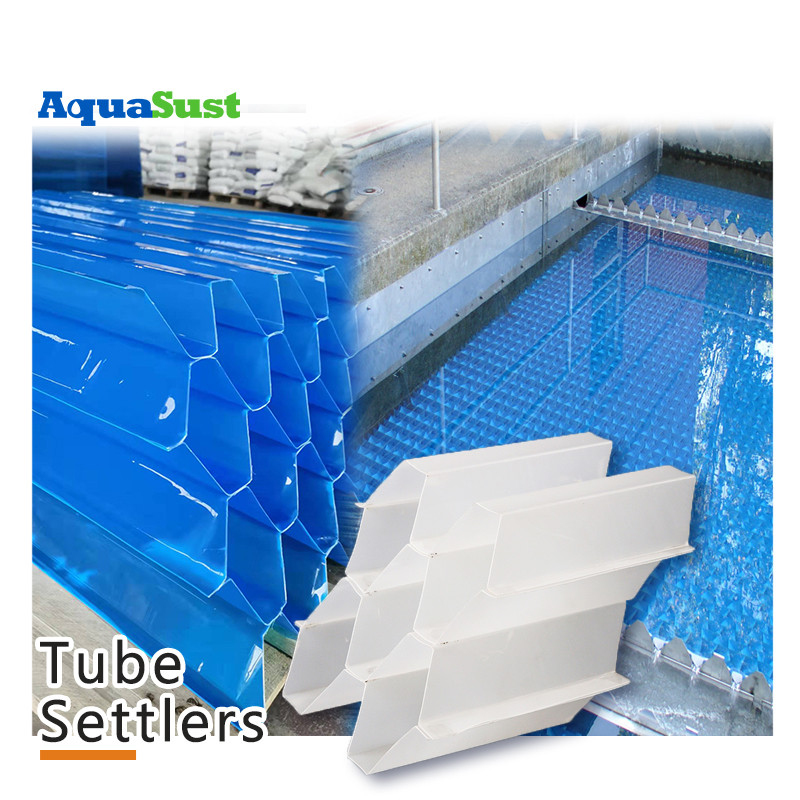

Welded Gun For PP Tube Settlers

PP Tube settlers:

1.Wall thickness less than 0.6mm, we should use 100W welded gun, and the welded time is not 30 seconds.

2.Wall thickness less than 1.0 mm and more than 0.6mm, we should use 200W welded gun, and the welded time is not 5 seconds.

3.Wall thickness less than 1.4mm and more than 1.0mm, we should use 300W welded gun, and the welded time is not 15 seconds.

Recommended accessories:

Disc Diffuser

Tube Diffuser

Tube Settler

Dewatering Machine