High-Efficiency Roots Blowers For Textile And Dyeing Wastewater Treatment

- Model

- AS-SL7018

Review

Description

Working Conditions and Principles

There are two impellers on two parallel shafts, and there is always a small gap between the impellers and the inner hole surface of the oval case and the impellers, because the impellers rotate at a constant speed in the opposite direction to each other, so that a certain amount of gas surrounded by the case and the impellers is transported from the side of the inhalation to the side of the discharging.

The impellers always keep the correct phase and do not collide with each other, so it can be high speed and does not need internal lubrication, and the structure is simple, the operation is smooth, the performance is stable, and it is suitable for many purposes, and it has been used in a wide range of fields.

Product Features

1. The impeller and shaft adopt the structure form of integral casting, with good overall machining precision.

2. Helical gear structure, smooth transmission, low noise.

3. Adopting CR brand fluoroelastomer oil seals and labyrinth air seals made of PTFE, which have good abrasion resistance and high-temperature resistance.

4. The gear ends use double-row ball bearings for durability.

5. Cylindrical roller bearings are used at the drive end. Its ability to withstand vertical loads is greatly enhanced.

6. Utilizes Tuthil's proprietary noise-reducing cylinder design to reduce the noise of the turbine mainframe.

7. Versatility of mounting, the blower can be mounted with the same feet for both horizontal and vertical air intake, with the ability to change the position of the drive shaft, right or left, top or bottom.

8. Dual tank structure, both at the gear end and at the drive end uses flash lubrication, better heat dissipation, and lubrication effect on bearings and gears Gear lubrication overall machining precision.

Roots Blower in Textile And Dyeing Wastewater Treatment Applications:

1.Bioreactor Aeration

In the biological treatment of textile printing and dyeing wastewater, Roots Blower is used for bioreactor aeration to provide sufficient oxygen to promote the growth of aerobic microorganisms and the degradation of organic matter.

2.Activated sludge system

In the activated sludge system, Roots Blower is used to provide continuous airflow to maintain high dissolved oxygen concentration, promote flocculation and settlement of activated sludge, and improve sludge treatment and wastewater purification.

3. Membrane Bioreactor (MBR)

In a membrane bioreactor, the airflow provided by Roots Blower not only helps oxygen transfer, but also reduces membrane contamination, extends membrane life, and improves the treatment efficiency of the MBR system.

4.Sludge Treatment

In the sludge treatment unit, Roots Blower facilitates the aerobic stabilization process of sludge by providing airflow, which reduces the volume of sludge and the content of hazardous substances, and improves the treatment effect of sludge.

5. Wastewater Homogenizer

In the Wastewater Homogenizer, Roots Blower is used to maintain a homogeneous mixing of wastewater, preventing the settling of suspended solids and improving the treatment efficiency of the subsequent treatment units.

Recommended accessories:

Disc Diffuser

Tube Diffuser

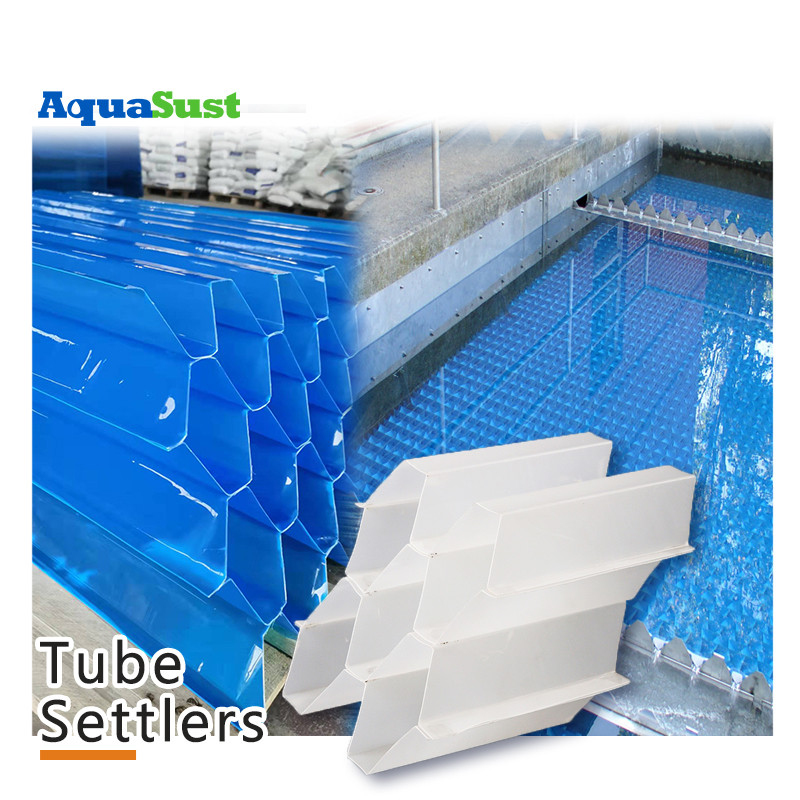

Tube Settler

Dewatering Machine