Silicone Tube Diffusers and Their Application in Lift-Type Systems

- Share

- publisher

- Kate

- Issue Time

- Sep 4,2025

Summary

This article introduces silicone tube diffusers and liftable aeration systems for wastewater treatment. Silicone diffusers provide high chemical stability and clog resistance. Three liftable systems—frame-based, manual, and suspended-chain—are highlighted. These systems enable maintenance without draining tanks, reduce downtime, and lower operating costs, offering flexible and efficient aeration solutions.

By: Kate Nana

Post Date: Sep. 4th, 2025

Email:Kate@aquasust.com

Post Tags: Tube diffuser,Water Treatment ,Aerationtank ,Wastewater Solutions ,Liftable tube diffusers,Liftable aeration tube

The application of fine bubble aeration systems in wastewater treatment processes is already widespread. Among these, tube diffusers made of silicone rubber have garnered significant attention due to their material properties. Meanwhile, as the operational and management standards of wastewater treatment plants improve, the demand for renovating and maintaining aeration systems without the need to stop water flow or empty tanks is increasing.

Introduction to Aquasust Silicone Tube Diffusers

1.1 Material Properties

The membrane of the microporous tube diffuser made of silicone rubber offers excellent chemical stability, resistance to acids and alkalis, high mechanical strength, and strong impact resistance, enabling it to withstand water hammer effects caused by frequent fan activation. Additionally, the surface of its air distribution layer is specially treated with electrostatic processing, making it smooth and less prone to microbial attachment. Since silicone rubber does not contain plasticizers, long-term use is less likely to cause an increase in resistance loss due to aging. Furthermore, the surface of the diffuser is not easily clogged, ensuring a long service life. Due to its thin air distribution layer, short pore channels, and smooth, fine porous structure, the interior is less likely to be clogged by impurity particles in the air, resulting in lower requirements for air cleanliness. Generally, there is no need to install specialized air purification equipment to remove dust from the air entering the blower.

1.2 Low-Pressure Loss Air Distribution Structure

The silicone rubber microporous tube diffuser adopts a unique structural design that effectively reduces pressure loss during operation. During aeration, the diffuser forms an air distribution layer between the support tube and the air distribution layer, ensuring uniform air distribution along the length of the diffuser while reducing air resistance loss and its rate of increase. Typically, the initial resistance loss of the tube diffuser is 3.5–4.5 kPa. Although this is higher than that of disc-type and corundum diffusers, its unique structural design and the excellent performance of the membrane result in a slower rate of resistance loss increase during operation, thereby achieving the goal of reducing pressure loss.

2.1 Design Description and Case Study of Liftable Aerators

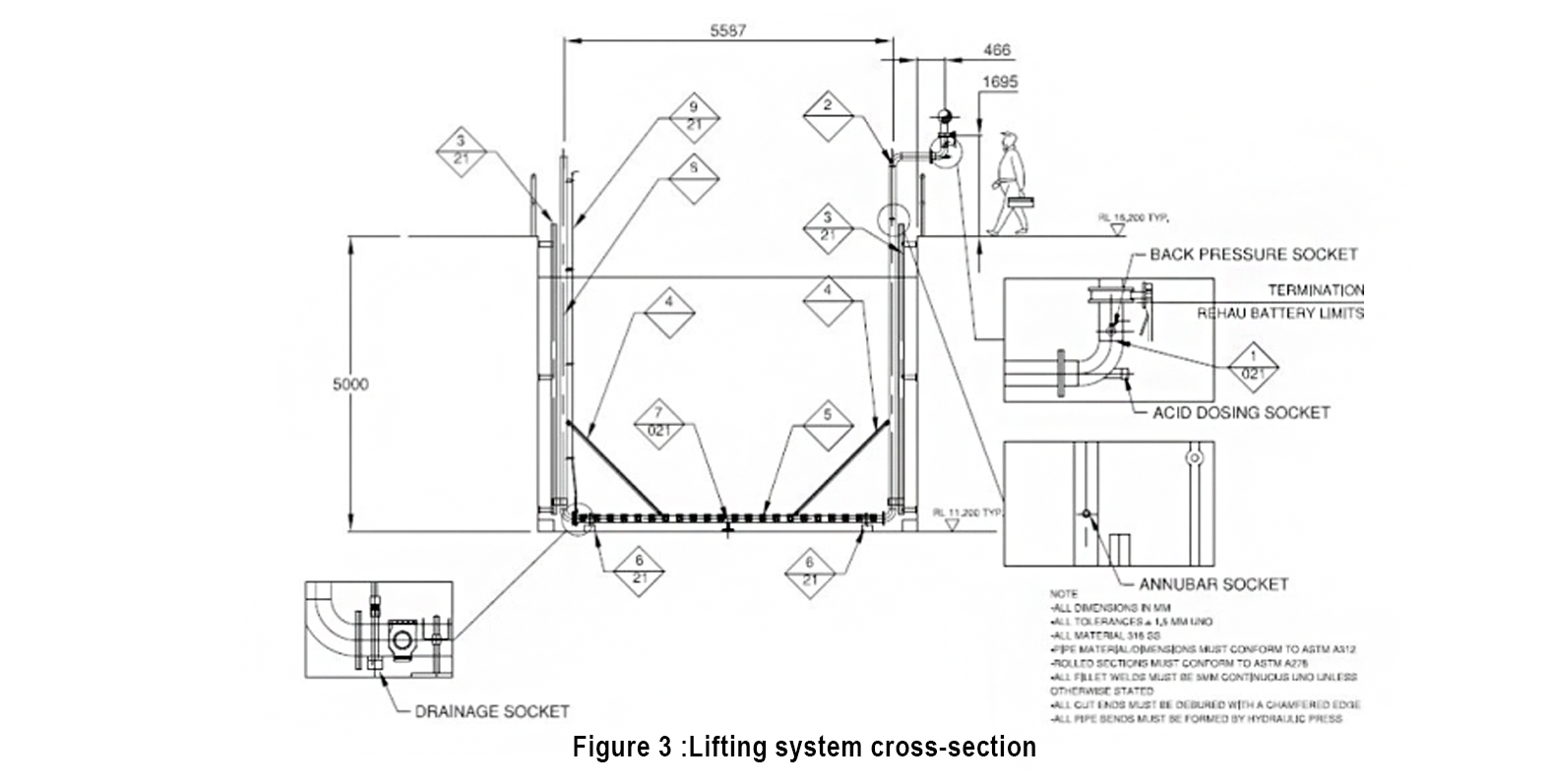

The integrated frame-type aeration system utilizing a hoisting device for lifting, also known as the mechanically liftable aeration system, employs a holistic frame-based design. In terms of layout at the bottom of the tank, it does not differ significantly from conventional aeration systems fixed to the tank floor. Typically, fine bubble aeration tubes or larger diameter aeration discs are used, accompanied by piping made of stainless steel.

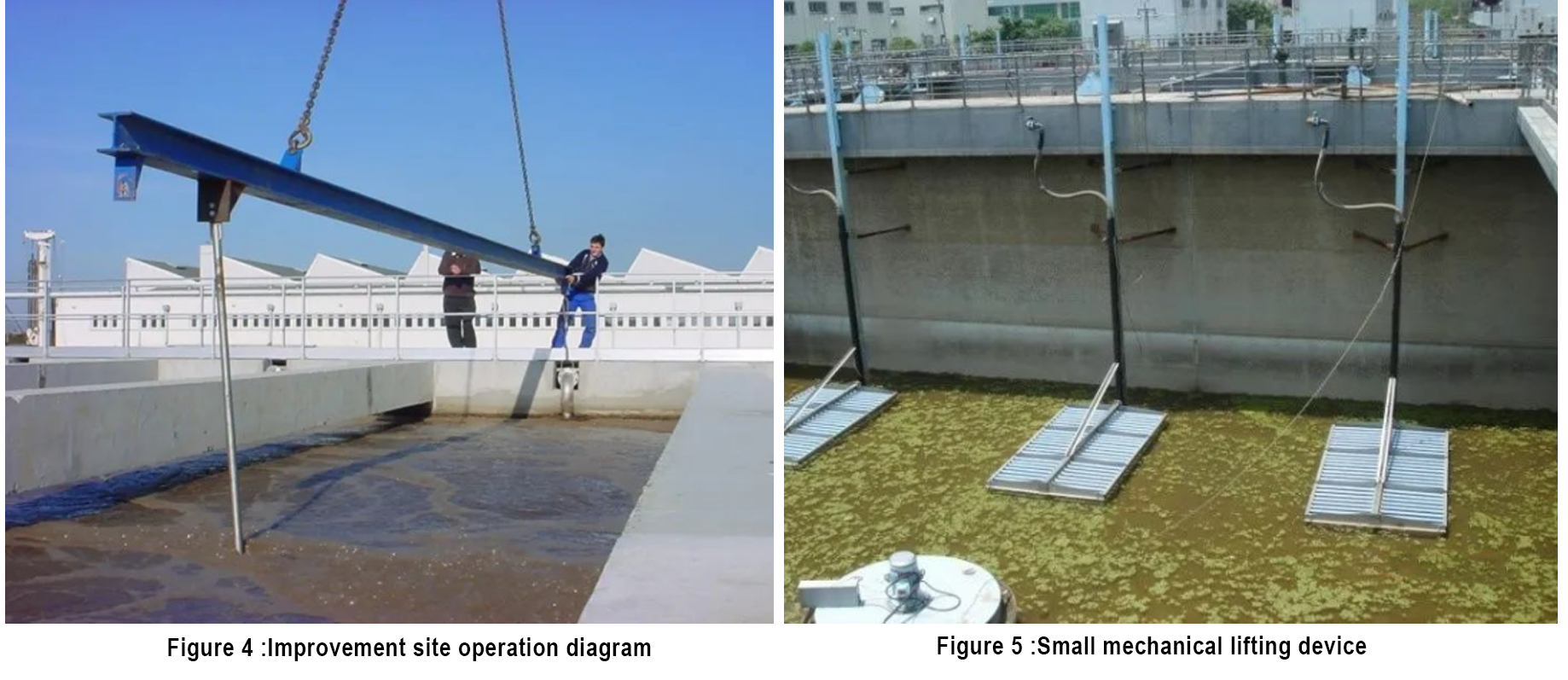

As shown in the cross-sectional diagram below (Figure 3), the integrated frame-type system mainly consists of five components: the bottom aeration system, vertical pipes and lifting pipes, guide rail system, lifting beam, and hoisting equipment. For maintenance, there are two options for hoisting: a small hoisting device installed on the walkway plate (Figure 5) or a large mechanical crane (Figure 6).

2.2 Manually Liftable Diffuser System

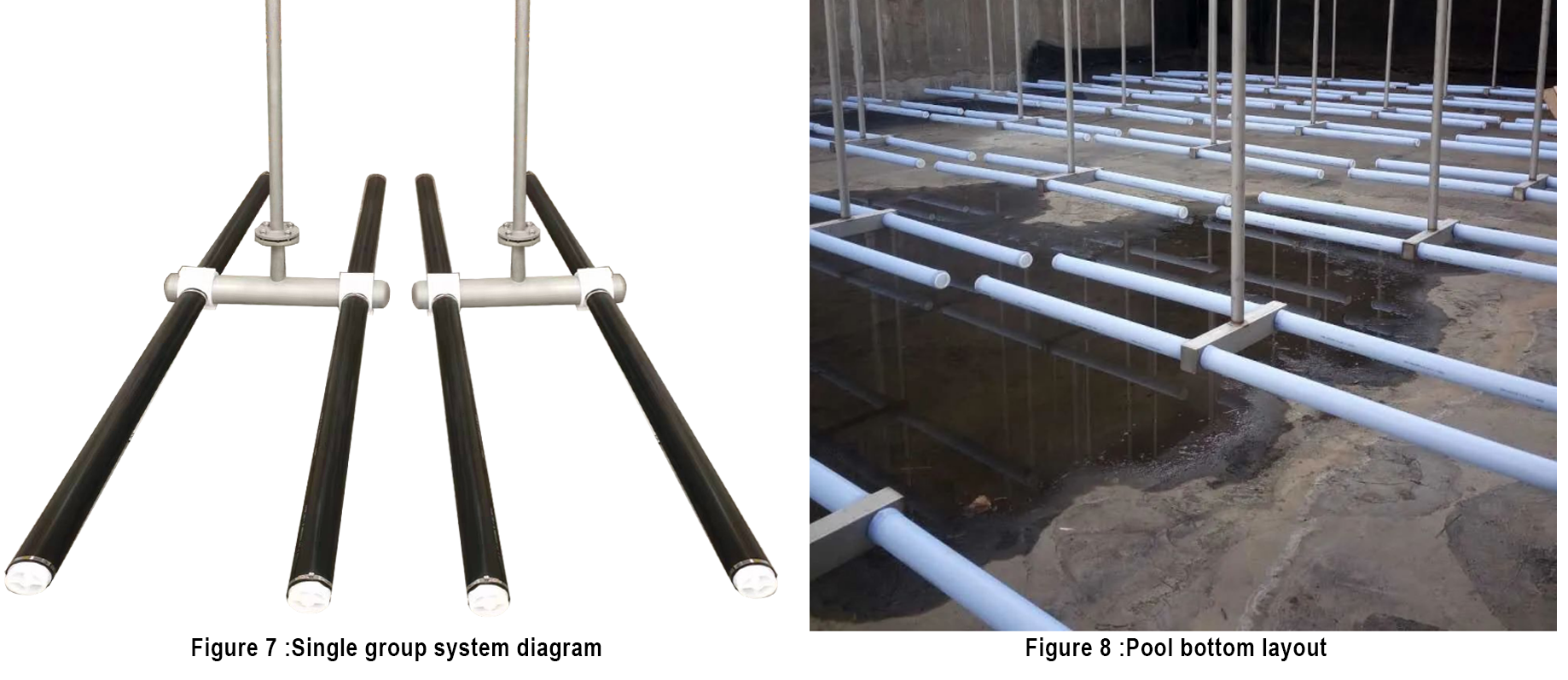

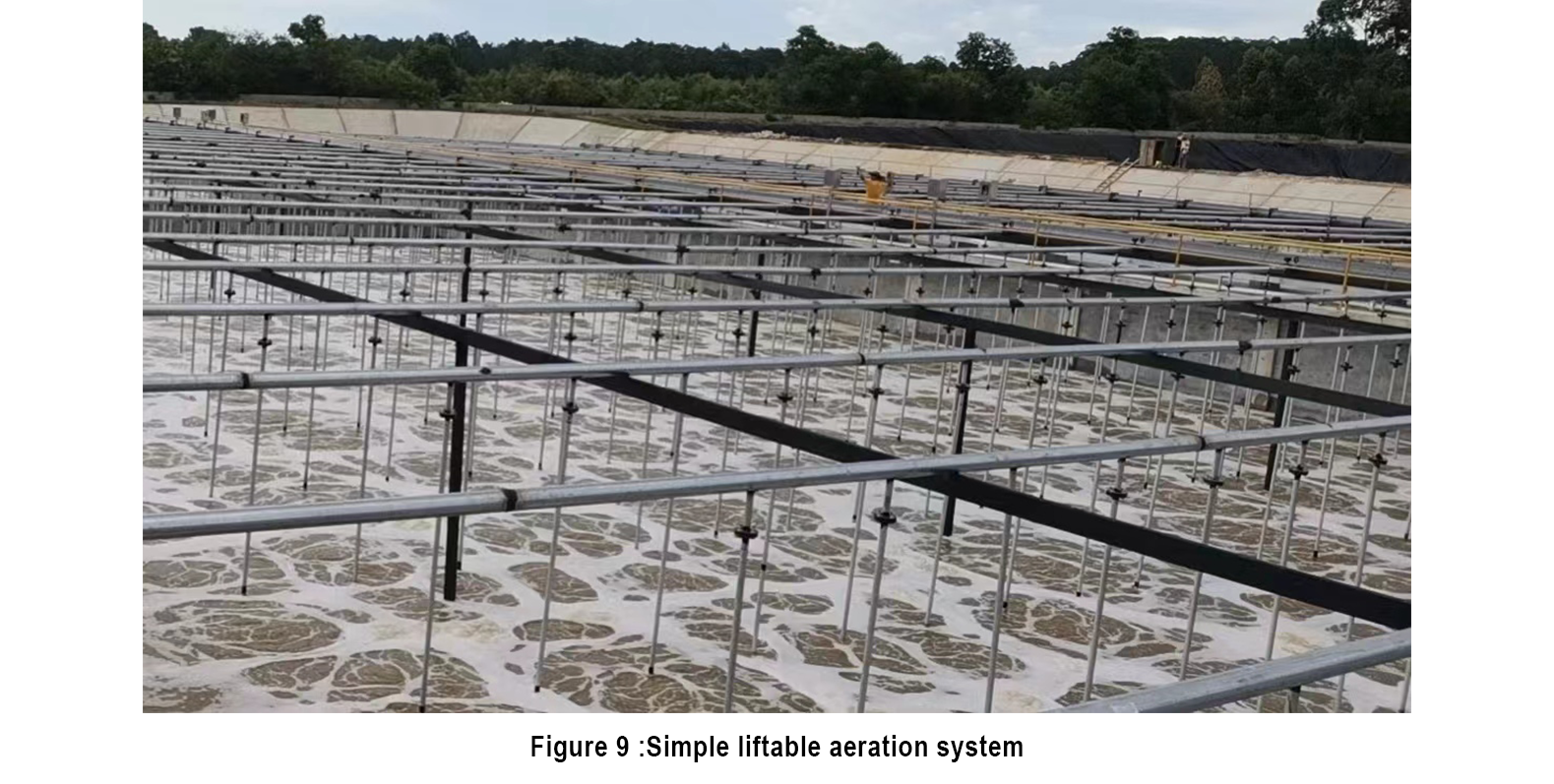

The simple liftable aeration system is designed to be manually hoisted. During maintenance, the diffusers can be handled by operators using basic tools. The system consists of stainless steel pipes and aeration tubes, typically configured in modular units of 4-meter long aeration tubes (as shown in Figures 7 and 8).

At an industrial wastewater retrofit project site, the original aeration system in the biological tank consisted of diffuser discs fixed to the bottom. Due to the long downtime and high costs associated with maintaining the existing aeration system, the client required a renovation that could be carried out without interrupting wastewater treatment. After assessing the site conditions, the engineers proposed a simple liftable solution.

This solution involved modifications to the main air pipes on the top of the tank. Some sections of the main pipes were installed with the assistance of a crane, while the vertical pipes and in-tank aeration units were installed manually using a small boat. This approach significantly reduced both the construction time and the required working area.

To prevent collisions between the new aeration tubes and the existing diffuser discs during installation, professional surveying of the installed height of the original discs was necessary beforehand. Additionally, in areas equipped with mixers or near turning points of the corridors within the biological tank, the simple liftable aeration system was not recommended, to avoid potential damage to the vertical pipes caused by water flow impact.

2.3 Suspended Chain Aeration System

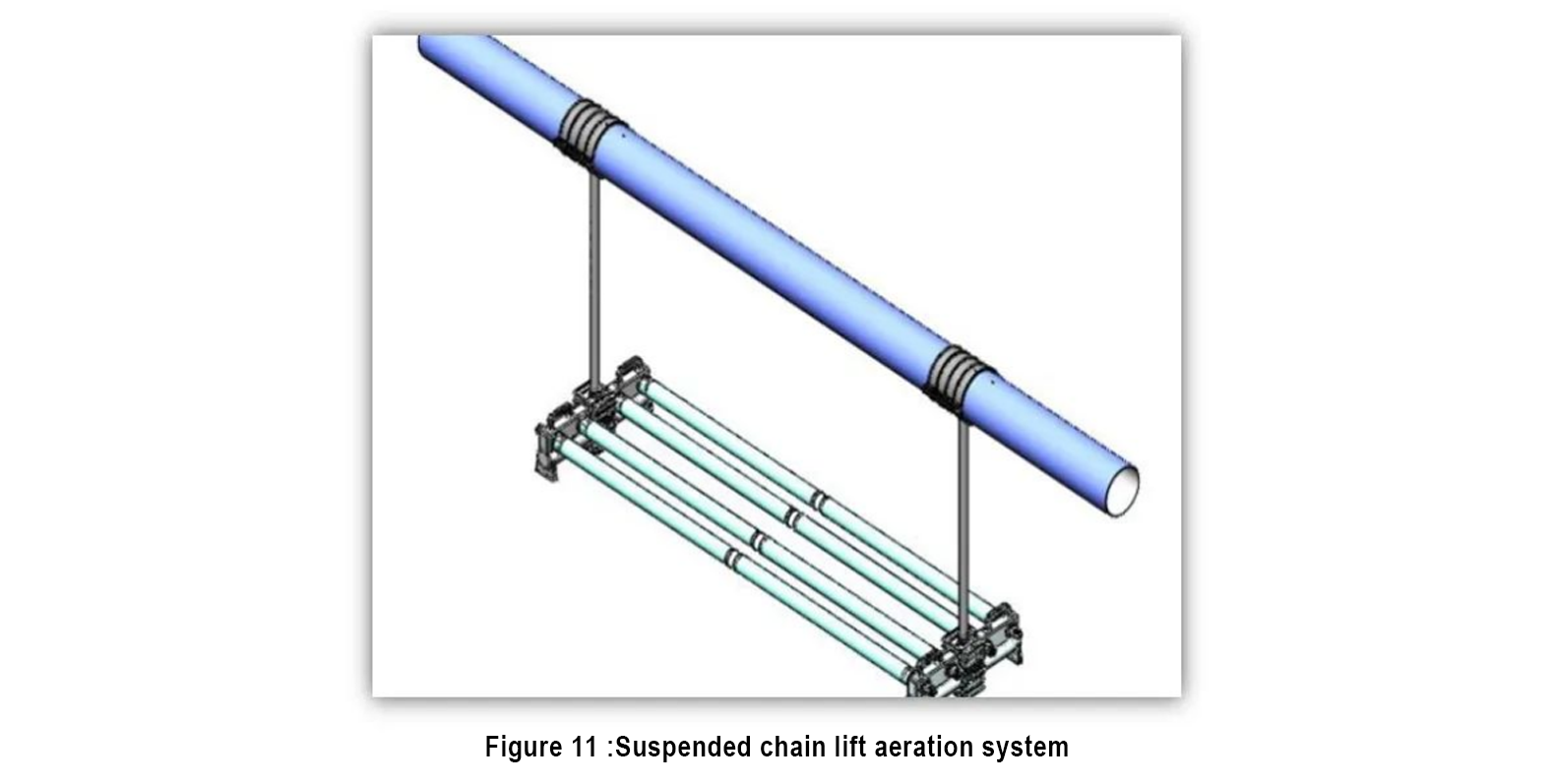

As the name implies, the suspended chain aeration system is designed with aeration units suspended from the main air distribution pipe. A single suspended chain aerator unit consists of the following components (see Figure 11): four rows of aeration tubes, each with a length of 2 meters, along with fixed supports at both ends, forming one complete set. The unit is connected to the main air distribution pipe via flexible hoses and floats suspended in the wastewater to provide oxygen aeration, mixing, and blending.

Aquasust provides comprehensive wastewater treatment solutions(mbbr media water treatment) and is a professional supplier(mbbr media suppliers) of sewage treatment equipment. We manufacture core products including MBBR media, Disc diffusers, Tube diffusers, Drum Filter and Tube settlers, committed to delivering high-quality products for the global water treatment sector.