Principle of Overlapping Screw Sludge Dewatering Machine

- Share

- publisher

- Kate

- Issue Time

- Sep 23,2025

Summary

Principle of Screw Press Sludge Dewatering Machine

By: Kate Nana

Post Date: Sep. 23, 2025

Post Tags: Sludge Treatment Technology,Sludge Dewatering,Screw Press Sludge Dewatering Machine,Industrial Sludge Treatment

The Screw Press Sludge Dewatering Machine is a type of spiral extrusion dewatering equipment. It eliminates the need for sedimentation tanks and sludge thickening tanks, thereby reducing the construction cost of wastewater treatment plants. This system utilizes an innovative multi-ring self-cleaning filtration technology instead of traditional sieve filtration. The self-cleaning mechanism ensures continuous and stable solid-liquid separation. Through the powerful squeezing force generated by the gradually changing diameter and pitch of the screw, as well as the narrow gaps between the moving and fixed rings, the sludge is effectively dewatered. This makes it an advanced solid-liquid separation solution.

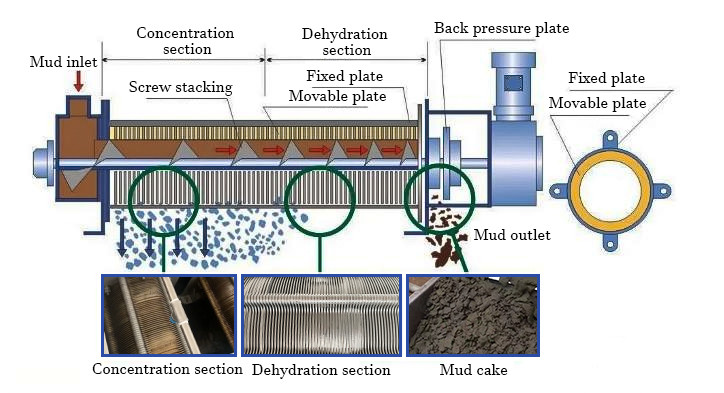

Structural Principle

1. The main body of the dewatering machine consists of a filtration device formed by multiple fixed and moving rings stacked alternately, with a spiral shaft running through them. The front section is the concentration zone, and the rear section is the dewatering zone.

2. The gap between the fixed and moving rings and the pitch of the spiral shaft gradually decrease from the concentration zone to the dewatering zone.

3. As the spiral shaft rotates, it transports the sludge from the concentration zone to the dewatering zone while continuously driving the moving rings to clean the gaps, preventing clogging.

4. After being gravitationally thickened in the concentration zone, the sludge is conveyed to the dewatering zone. As it moves forward, the gradually reducing gap and screw pitch, along with the resistance created by the back-pressure plate, generate significant internal pressure. This progressively reduces the volume of the sludge, achieving efficient dewatering.

Dewatering Mechanism

After gravitational thickening in the concentration zone, the sludge is transported to the dewatering zone. As it advances, the gradually narrowing gaps between the rings, the reduced screw pitch, and the resistance from the back-pressure plate create intense internal pressure. This results in a continuous reduction in sludge volume, ensuring thorough dewatering.