How to Control Sludge Bulking in Aeration Tanks

- Share

- Issue Time

- Nov 7,2024

Summary

Sludge bulking is a common abnormal condition in the activated sludge process , resulting in poor settling performance, failing to meet the requirements for oxidizing and decomposing pollutants, ultimately resulting in an effluent BOD5 level exceeding standards .

How to Control Sludge Bulking in Aeration Tanks

Sludge bulking is a common abnormal condition in the activated sludge process, occurring when activated sludge becomes lighter and more expanded due to certain changes, resulting in poor settling performance. This prevents normal sludge-water separation in the secondary settling tank, causing sludge to be discharged with the effluent. If bulking is not controlled, the loss of sludge will cause effluent suspended solids (SS) levels to exceed standards. Continued sludge loss can lead to a sharp reduction in microorganisms in the aeration tank, failing to meet the requirements for oxidizing and decomposing pollutants, ultimately resulting in an effluent BOD5 level exceeding standards.

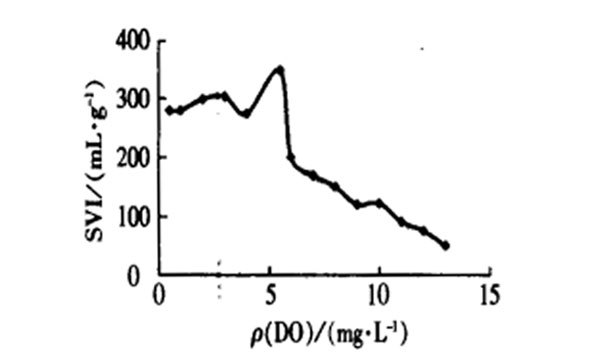

The optimal settling performance occurs when the sludge volume index (SVI) is around 100. When SVI exceeds 150, sludge bulking is imminent or has already occurred, necessitating immediate control measures. Generally, sludge bulking can be classified into two main types: filamentous bulking and non-filamentous bulking.

· Filamentous bulking results from the excessive proliferation of filamentous bacteria in sludge flocs.

· Non-filamentous bulking is due to abnormal bacterial activity within flocs, leading to excessive production of sticky substances.

Causes and Conditions for Filamentous Bulking

Normal activated sludge contains some filamentous bacteria, forming the framework of sludge flocs. If filamentous bacteria are too few, large flocs cannot form, resulting in poor settling. Excessive proliferation of filamentous bacteria, however, leads to filamentous bulking. In a stable environment, floc-forming bacteria usually outgrow filamentous bacteria. However, if conditions deteriorate, filamentous bacteria, with their larger surface area, may resist environmental changes better, outnumbering floc-forming bacteria and causing filamentous bulking. Conditions contributing to this include:

1.Low organic matter in influent, resulting in a low F/M (food-to-microorganism) ratio and insufficient microbial food.

2.Insufficient nitrogen and phosphorus nutrients.

3.Low pH levels, which inhibit microbial growth.

4.Low dissolved oxygen in the aeration tank, inadequate for microbial needs.

5.Large fluctuations in influent quality or quantity, causing stress on microorganisms.

6.The presence of high H2S levels (above 1-2 mg/L) from septic influent, fostering overgrowth of sulfur bacteria, leading to filamentous bulking.

7.Suitable temperatures for filamentous bacteria growth range from 25°C to 30°C, making bulking more common in summer.

Causes and Conditions for Non-filamentous Bulking

Non-filamentous bulking occurs when bacterial activity within the floc deteriorates, worsening sludge settling performance, and can be divided into two types. The first is caused by high levels of dissolved organic matter in influent, resulting in a high F/M ratio, while nitrogen, phosphorus, or dissolved oxygen is deficient. Under high F/M, bacteria absorb large amounts of organic matter but lack the nutrients or oxygen needed for normal metabolism, leading them to secrete excess polysaccharides. These hydrophilic substances can increase sludge-bound water to over 400% (compared to the typical 100%), forming a sticky gel that hinders effective sludge-water separation and concentration in the secondary settling tank—referred to as sticky bulking. The second type occurs when toxic substances in influent poison the sludge, preventing bacteria from secreting adequate sticky substances, which inhibits floc formation and sludge-water separation, often termed non-sticky or dispersed bulking.

Control Measures for Sludge Bulking

Measures to control sludge bulking in the aeration tank can be classified into three types: temporary control measures, operational control adjustments, and permanent control measures.

1.Temporary Control Measures: Used to manage sludge bulking caused by temporary conditions, preventing sludge loss and elevated SS levels. Temporary controls include the use of coagulants to aid sedimentation (mainly for non-filamentous bulking) and the application of biocides to inhibit filamentous bacteria growth.

(1)Coagulants: Additives like polyaluminum chloride or ferric chloride help strengthen sludge aggregation for better sludge-water separation. Coagulants can be added to the inlet or outlet of the aeration tank. The recommended dose is around 10 mg/L for alumina-based coagulants.

(2)Biocides: Chemical agents like chlorine, sodium hypochlorite, and hydrogen peroxide can be used to inhibit filamentous bacteria. Doses should start low and increase gradually, monitoring SVI values and microscopic examination until optimal results are reached.

2.Operational Control Adjustments:

Effective for preventing bulking caused by improper process control. Techniques include:

Adding clay or lime to the aeration tank inlet to improve sludge settling and density.

①Pre-aerating influent to ensure oxygen availability and avoid anaerobic conditions, preventing H2S formation.

②Increasing aeration intensity to boost dissolved oxygen.

③Supplementing nitrogen and phosphorus to maintain balanced nutrition.

④Increasing sludge return rates to shorten sludge residence time in the secondary clarifier and avoid anaerobic conditions.

⑤Adjusting pH with alkaline substances when necessary.

3.Permanent Control Measures:

These involve facility modifications or design improvements for new or upgraded systems to prevent sludge bulking or provide preemptive control. One common approach is installing biological selectors before the aeration tank, promoting the growth of floc-forming bacteria over filamentous bacteria. Types of selectors include:

(1)Aerobic Selector: Provides high-load zones rich in dissolved oxygen and organic material, promoting the growth of floc-forming bacteria over filamentous bacteria.

(2)Anoxic Selector: Enables floc-forming bacteria to use nitrate as an oxygen source, which filamentous bacteria cannot utilize, thus controlling filamentous growth.

(3)Anaerobic Selector: Inhibits most aerobic filamentous bacteria while supporting facultative anaerobes, though care is needed to prevent sulfur-producing filamentous bacteria.

These control measures, chosen based on the specific causes of bulking, can stabilize sludge performance, ensure SS and BOD5 standards, and improve system reliability.