Best Practices for Maintaining MBBR Integrated Wastewater Treatment Units

- Share

- publisher

- Kate

- Issue Time

- Sep 17,2025

Summary

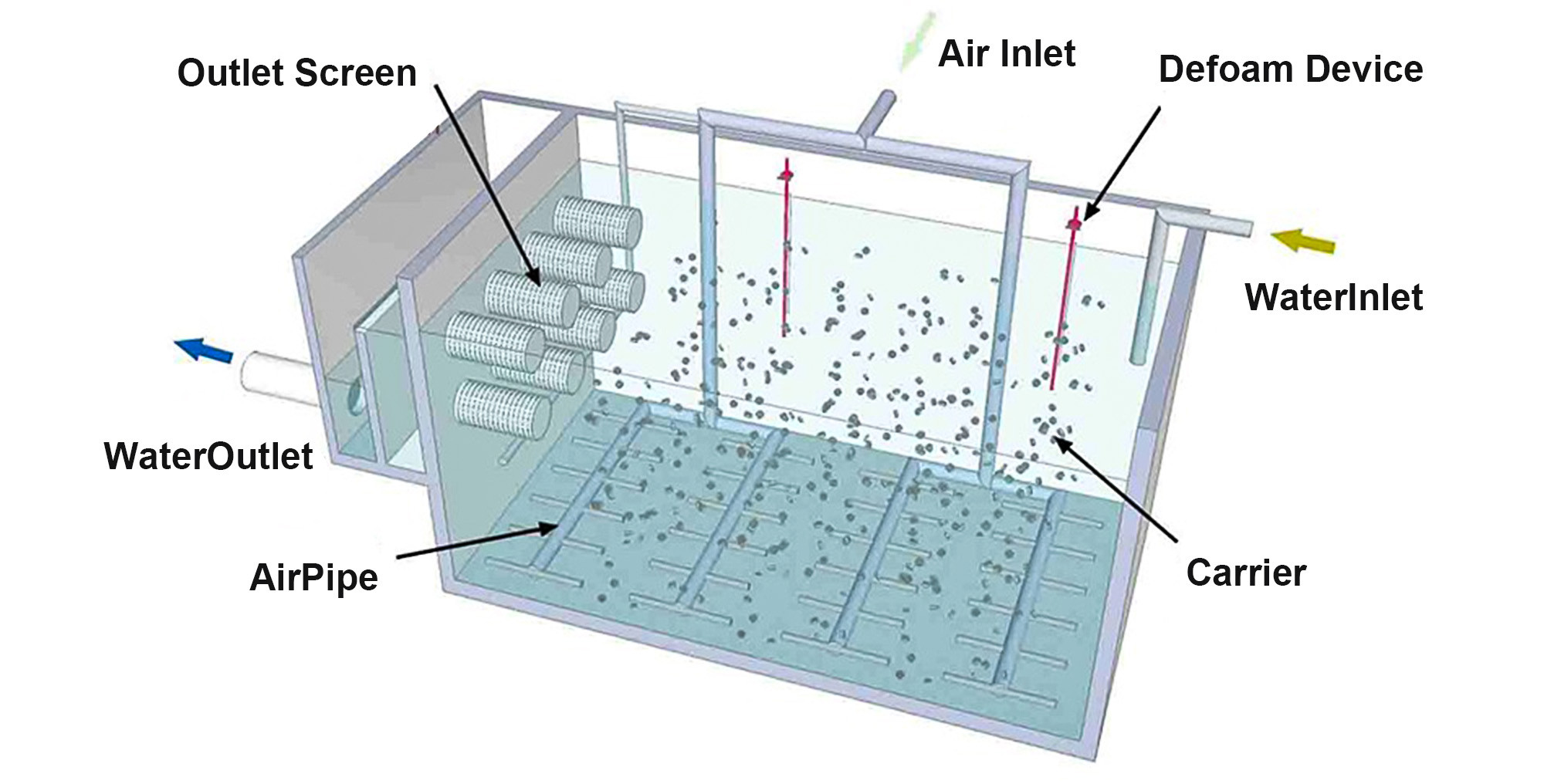

The MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment system primarily consists of three parts: the reactor body, suspended bio-carriers, and the bottom fine bubble diffuser (Disc Diffuser / Tube Diffuser).

By: Kate Nana

Post Date: September 17th, 2025

Email:Kate@aquasust.com

Post Tags: MBBR, Secondary Wastewater Treatment, MBBR System,Moving Bed Biofilm Reactor (MBBR)

MBBR Integrated Sewage Treatment Equipment

The MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment system primarily consists of three parts: the reactor body, suspended bio-carriers, and the bottom fine bubble diffuser (Disc Diffuser / Tube Diffuser). The suspended bio-carriers have a large specific surface area that supports extensive biofilm growth on both internal and external surfaces. These carriers have a density close to that of water, allowing them to move freely within the sewage. Under the aeration and mixing action provided by the fine bubble diffuser at the bottom, the suspended carriers collide with each other and undergo rotational or turning movements within the reactor. This enhances the transfer of liquid-phase organic matter and promotes biofilm renewal. Organic compounds and suspended solids in the wastewater are captured and adsorbed by the biofilm, which serves as a nutrient source for microbial growth. These substances are subsequently metabolized during microbial reproduction, thereby achieving efficient sewage degradation.

Maintenance Tips for MBBR Integrated Sewage Treatment Equipment

Daily Inspection: Check daily the operational status of the equipment, including influent and effluent quality, treatment efficiency, noise, and vibration. If any abnormality is detected, the system should be shut down promptly for troubleshooting.

Cleaning and Maintenance: Regularly remove accumulated dirt and sediments from the surface and internal parts of the equipment. Key areas such as the inlet, outlet, and filter screen must be kept clean and unclogged. All parts of the equipment should be cleaned thoroughly, keeping both the interior and exterior free from oil, rust, dust, and debris—especially sliding rails and joints.

Lubrication Maintenance: Apply lubricating oil or grease periodically to transmission parts and bearings to reduce wear and friction and extend service life.

Electrical Inspection: Inspect electrical components such as motors, controllers, and switches to ensure normal operation. Replace any damaged or aged parts in a timely manner.

Safety Protection Check: Examine all safety protection devices to ensure they are intact, secure, flexible, accurate, and reliable.

Fastener Check: Inspect and tighten all screws in the equipment to prevent loosening during operation.

Pipeline Inspection: Check all pipelines and fittings to ensure they are in good condition, with no leakage, spillage, dripping, or seepage.

Aquasust provides comprehensive wastewater treatment solutions(mbbr media water treatment) and is a professional supplier(mbbr media suppliers) of sewage treatment equipment. We manufacture core products including MBBR media, Disc diffusers, Tube diffusers, Drum Filter and Tube settlers, committed to delivering high-quality products for the global water treatment sector.